The intricate world of batt insulation R-values unveils a nuanced understanding of thermal dynamics within building structures.

As a fundamental metric for assessing insulation efficiency, the R-value of batt insulation represents a critical parameter that demands meticulous consideration.

From the interplay of material characteristics to the strategic deployment of varying thicknesses, every facet influences the insulation's ability to regulate heat transfer.

Delving deeper into the realm of batt insulation R-values reveals a tapestry of intricacies that shape the thermal performance of buildings, offering a glimpse into the strategic choices and technical nuances that underpin optimal insulation solutions.

Batt insulation R-Value, a crucial metric in determining the thermal resistance capability of the material, plays a pivotal role in assessing its effectiveness in insulating various spaces.

Typically falling between R-3 and R-4 per inch, batt insulation can achieve up to R-60 based on thickness variations.

The higher the R-value, the better the insulation performance, aiding in reducing energy consumption and maintaining comfortable indoor temperatures while cutting utility costs.

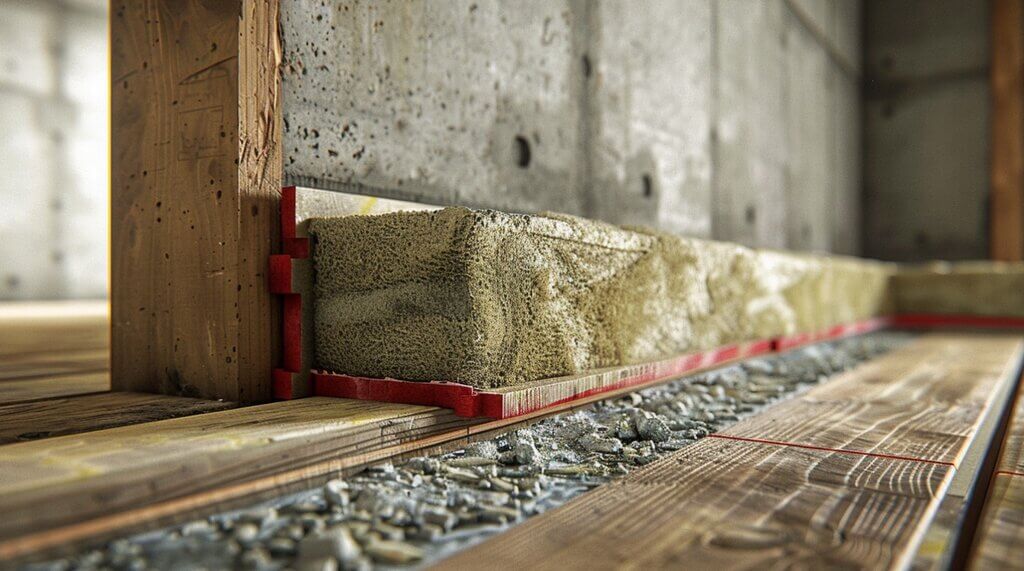

Available in pre-cut batts or rolls made of materials like fiberglass, wool, plastic, or organic fibers, batt insulation finds common applications in walls, attics, floors, and ceilings, offering both thermal and acoustic insulation benefits.

Proper selection of batt insulation with the appropriate R-value is essential for maximizing thermal efficiency in residential and commercial structures.

Factors influencing the R-Value of insulation include the type of material used, its thickness, and density, all of which play a significant role in determining the effectiveness of the insulation in thermal resistance.

The material type affects how well the insulation resists heat flow, with materials like fiberglass, cellulose, and foam each having different thermal conductivity properties.

Thickness directly impacts the R-Value, as thicker insulation provides more resistance to heat transfer. Density is crucial as denser insulation typically has a higher R-Value due to reduced air pockets within the material.

Proper installation is essential to maintain the intended R-Value, ensuring gaps or compression that can compromise insulation performance are avoided.

Environmental factors like moisture and temperature can also influence the longevity and efficiency of insulation over time.

In determining the ideal R-values for different climates, it is essential to consider specific recommendations tailored to optimize energy efficiency and comfort in varying regions.

Climate-specific R-value guidelines play a crucial role in maximizing energy efficiency and maintaining comfortable indoor temperatures across different geographical areas. By adhering to these recommendations, buildings can achieve enhanced thermal performance and potentially reduce utility costs.

What distinguishes various types of insulation in terms of their effectiveness and applications?

Different types of insulation offer varying levels of thermal resistance, durability, and additional benefits.

Fiberglass batt insulation, for example, is known for its versatility, offering options with different R-values and moisture resistance capabilities.

Mineral wool batt insulation, on the other hand, not only provides thermal resistance but also offers fire protection and sound attenuation properties.

Each type of insulation, whether fiberglass or mineral wool, comes in pre-cut sheets and rolls, facilitating easy installation in various areas like walls, attics, floors, and ceilings.

Understanding the distinctions between these insulation types is essential for selecting the most suitable option based on specific project requirements.

High R-Value insulation plays a crucial role in enhancing energy efficiency and indoor comfort by providing superior thermal resistance capabilities. This type of insulation offers various benefits:

When installing batt insulation, precision in fitting pre-cut sections between designated structural components is essential to ensure optimal thermal performance and energy efficiency.

Proper installation techniques play a significant role in maximizing the insulation effectiveness of batts. Here are some key steps to follow during the installation process:

| Installation Steps | Description |

|---|---|

| Ensure precise fitting | Cut batts to the required size for a snug fit between studs, joists, or rafters. |

| Seal any seams or edges | Prevent air leakage by sealing all gaps, seams, and edges with appropriate materials. |

| Wear protective gear | Use gloves, masks, and goggles to protect against skin irritation and airborne particles. |

| Follow manufacturer guidelines | Adhere to the instructions provided by the manufacturer for optimal installation. |

| Comply with local building codes | Ensure that the installation meets the regulations set forth in local building codes. |

Continuing from the discussion on the installation process for batt insulation, the cost-effectiveness of batt insulation makes it a practical choice for achieving thermal efficiency in residential and commercial buildings.

With properly installed batt insulation, the initial investment can lead to long-term savings on heating and cooling costs, making it a wise financial decision for property owners looking to enhance energy efficiency.

In comparing batt insulation with roll insulation, the key distinction lies in their respective forms and applications.

Batt insulation typically comes in pre-cut sheets, fitting between framing members in walls, floors, and ceilings, offering ease of installation.

On the other hand, roll insulation is continuous and suitable for covering long spans such as attics and floors, providing quick coverage of large areas.

Both types offer varying R-values per inch, ranging from R-3 to R-4 and beyond based on thickness.

The choice between batt and roll insulation depends on factors like the application area and installation convenience, impacting the overall thermal efficiency of residential and commercial buildings.

| Batt Insulation | Roll Insulation | |

|---|---|---|

| Form | Pre-cut sheets | Continuous roll |

| Application | Fits between framing members | Covers long spans like attics and floors |

| Installation | Easy installation in specific spaces | Quick coverage of large areas |